Next step for MOONRISE: Moon dust melted under lunar conditions

Even though the MOONRISE project has not yet arrived on the moon itself, it has now successfully completed an important step on the way there: For the first time, researchers were able to produce dense material under lunar conditions in the Einstein-Elevator in Hannover.

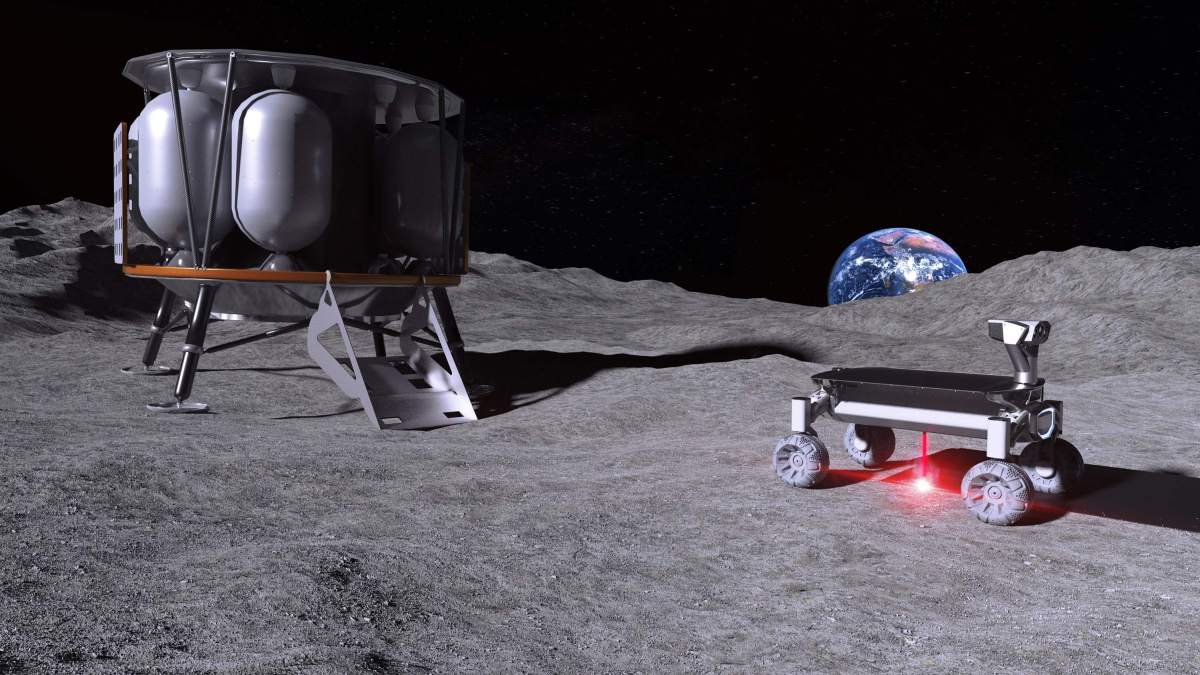

The long-term goal of the project is to make the dust on the moon usable as a building material for a research station, for example. To this end, the project partners, the Laser Zentrum Hannover e.V. (LZH) and the Institute of Space Systems (IRAS) of the Technical University of Braunschweig, want to melt the so-called regolith with the aid of a compact laser system and then convert it into versatile structures – 3D-printing on the moon. The MOONRISE film gives an exciting insight into their idea as well as the current status.

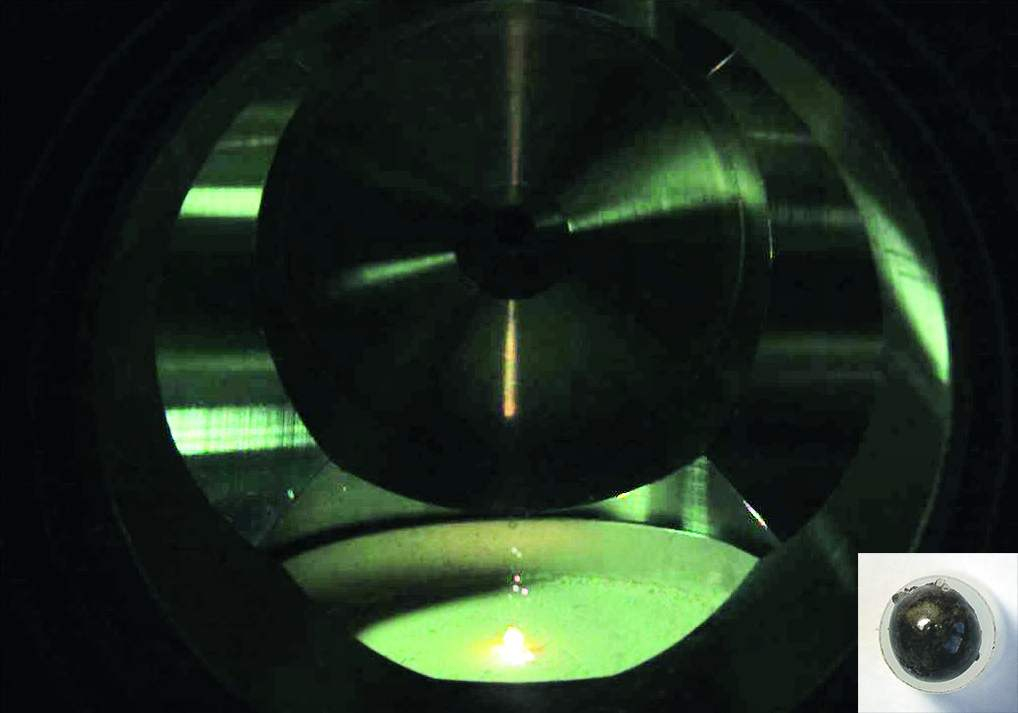

In an experiment in the Einstein-Elevator at the Hannover Institute of Technology of Leibniz University Hannover (LUH), the scientists now succeeded in generating small spheres from synthetically produced lunar dust – melted under the same conditions of gravity as on the moon. "With these spheres, we have taken a big step towards 3D-printing on the moon", explains Niklas Gerdes, scientific employee at the LZH.

The Einstein-Elevator is an actively controlled drop tower of a new generation. It enables experiments in weightlessness and other gravity conditions. For MOONRISE, the laser system and a vacuum chamber in the gondola of the elevator have been attached to an experiment carrier. The experiment carrier supplies the laser system with power and enables the controls over the system. The regolith samples are in vacuum during the experiments – just as they would be on the moon. During the flight, the laser melts a small amount of regolith, forming a sphere that cools down before landing in the experiment chamber.

The different samples of the regolith were assembled by scientists of IRAS. "Depending on the landing site of a possible lunar mission, the composition of the moon dust differs", explains Prof. Dr.-Ing. Enrico Stoll from IRAS. The mixtures would be used to simulate lunar conditions as accurately as possible and then to evaluate the quality of the melted samples. In this way the process could be further improved. The next major goal of the researchers is to test the laser system on a lunar mission. The forward-looking scientific project is being funded by the Volkswagen Foundation as part of the "Off the Beaten Track" funding initiative.